HX possesses an independent film blowing factory covering an area of over 15,000 square meters, with over 20 years of experience. Using the world's most advanced film blowing technology, equipment, and top pellet raw materials for independent research and development, is one of the world-renowned PE film suppliers.

Polypropylene Cloth made by HX is generally recognized by customers for its lightweight, good electrical insulation, high breaking strength, good chemical resistance, high abrasion resistance, and strong anti-aging ability.

Wholly-owned subsidiary by HX specializes in the E-wave Heating Pad which is made of graphene. The technology of this production is leading the world to adopt new heating materials and far-infrared electromagnetic waves for heating. The cooperation with flexitank provides a good transportation and packaging solution for the high melting point liquids.

HX independently develops and produces environmentally friendly cartons, cardboards, and paper rolls, which have the advantages of good moisture resistance, high strength, and strong buffer performance. Provide a strong guarantee for the liquid goods that are transported by the flexitank.

HX possesses the highest level of food-grade workshops in the industry. From raw materials to final products, quality is not only the core of research and development but also the driving force of goals. The quality of flexitank can be traced in the whole thirteen production process, to escort the loading safety of customers.

The plastic molding industry was established in 1992, which realized the independent supply of flexitank injection parts. Accumulated more than 30 years of experience and technology made HX become one of the injection suppliers of Haier, Hisense, Volkswagen, General Motors, LG Electronics, etc.

In 30 years,

Trust and recognition

from over

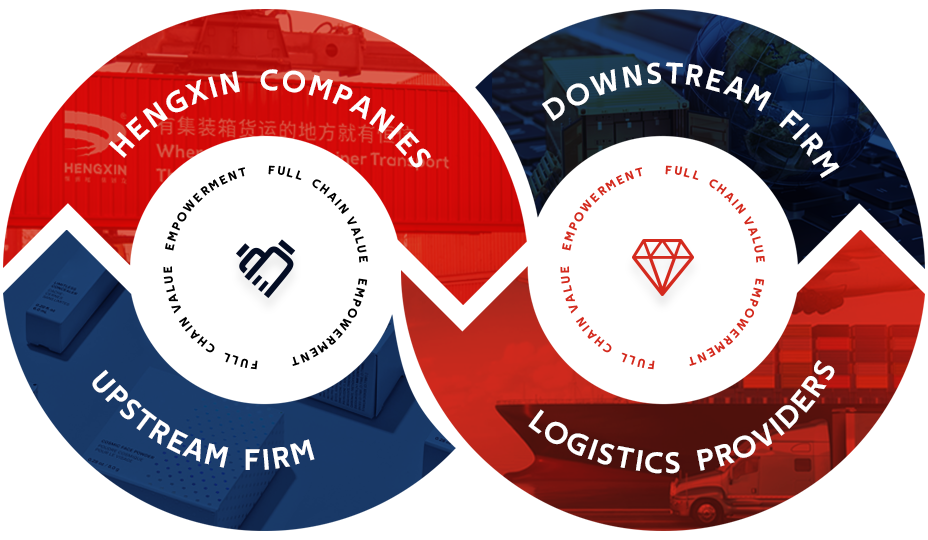

200 companiesHX is dedicated to building information platforms to connect upstream and downstream resources and assist customers to gain much more opportunities to realize win-win cooperation.